SIPOC – Simplifying IT process work

In a previous post, I encouraged simpler and better process maps. Furthering that discussion, I thought we could visit SIPOC, a tool that helps us to summarize and document our processes. SIPOC came about during the 1980’s in the quality movement and has since been applied in Six Sigma, Lean manufacturing and servicing, and business process mapping. Keep reading for simple instructions and a link to our template for SIPOC work!

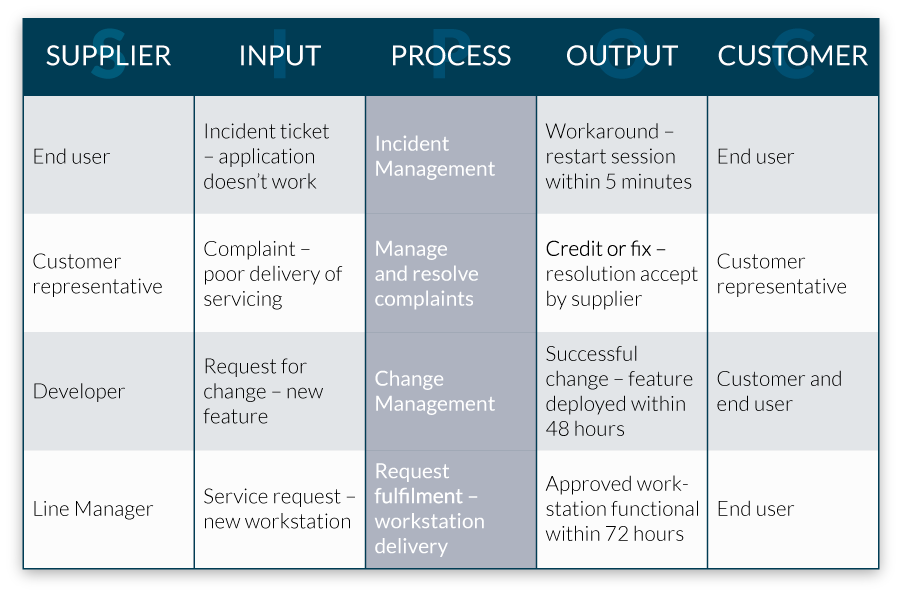

The name SIPOC comes simply from its five components – Supplier, Input, Process, Output, and Customer. A SIPOC diagram or table, simply summarizes these components, putting them in an understandable linear format. The purpose of SIPOC-diagrams is to create a clearer understanding of our work, on a high-level overview, thereby giving us the opportunity to produce and improve.

Some simple IT examples of SIPOC:

A SIPOC analysis is often a good first step in analyzing a work process because it helps us to create understanding. When ways of working are not effective, you can break them down by using the tool. Identify the S-I-P-O-C elements and start focusing on the areas that are unclear or incorrect.

SIPOC will help you to:

- Document ways of working.

- Identify critical input, output, and involved parties.

- Recognize needs and areas of improvement.

- Generate visual, easy-to-understand process illustrations.

- Communicate a process and improvement needs to others.

Process improvement does not to be difficult or hocus-pocus consultant work. As in all improvement, most important is to get started! Let SIPOC help. Learn more through a Lean IT course and our SIPOC guide. Good luck!

SIPOC step-by-step template and guide

Download our SIPOC guide with ready to go template and get started today!

Kundcase Restaurangkedjan - bättre kontroll på leveranser

Onbird hjälper restaurangkedjan få bättre kontroll på och kortare ledtider i IT-leveranser

När är ledarskapet det största hindret till flöde?

I vår strävan efter högre effektivitet, snabbare leveranser och bättre flöde är det lätt att förbise en avgörande faktor: ledarskapet. Ibland är det just vi som leder som skapar de största hindren för flöde och värdeskapande.

Kartläggning av värdeflöden

Att förstå hur arbetet faktiskt flyter genom organisationen från idé till kund är avgörande för att lyckas med förbättringar. Här berättar vi hur en värdeflödeskartläggning kan hjälpa dig till effektivare flöden, engagerade team och ökad kundnöjdhet.